ELBOWS: Mandrel method (Hot Forming)

- Categories:Product Information

- Author:Zhongran

- Source:Hebei Zhongran Pipeline Co., Ltd.

- Updated:2020-09-12

- Views:700

【Summary Description】

ELBOWS: Mandrel method (Hot Forming)

【概要描述】

- Categories:Product Information

- Author:Zhongran

- Source:Hebei Zhongran Pipeline Co., Ltd.

- Updated:2020-09-12

- Views:700

ELBOWS: Mandrel method (Hot Forming)

Introduction to Hot Forming

The principal methods of hot working are extrusion, drawing, forging and rolling. Rolling is the most extensive employed forming process, though some limitations may apply to the process. Rolling mainly consists of three major sub-categories: flat rolling, shape rolling (with specifically designed roll grooves) and pipe rolling (including piercing). Forging may be sub-categorized as hamming, pressing, etc.

Forging may be performed under hammers, in mechanical presses and upsetters or by a method known as roll forging. Pressing generally includes the manufacture of forged articles in hydraulic presses. Extrusion usually is performed in hydraulic presses which force the hot steel through a die. Rolling is performed in rolling mills of a variety of types.

The two principal reasons for perform metal forming at elevated temperatures (hot working) are to reduce the forming loads through the reduction of the resistance of the steel to deformation, and to develop preferred metallurgical structures for strength and ductility of the finish products.

The most appropriate manufacturing method of a product will be decided with consideration of its material, sizes, shape, use, standards and other properties.

There are numerous processes for manufacturing butt weld fittings, several examples listed as follows.

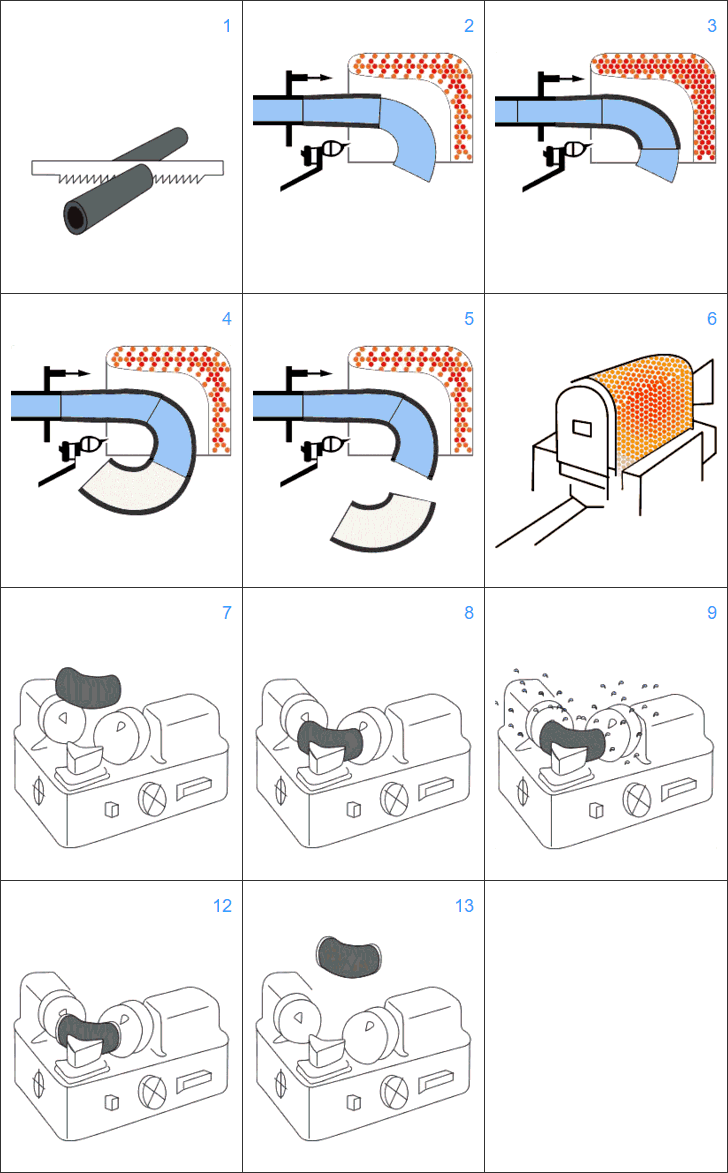

One of the most common manufacturing methods for manufacturing Elbows from pipes. After heating the raw material, it is pushed over a die called "mandrel" which allows the pipe to expand and bend simultaneously. Applicable to a wide size range.

Elbows of steel pipe joints are used in the industrial plants and are mainly manufactured by the hot mandrel bending from raw material of straight steel pipe. Elbows are generally manufactured at elevated temperature by means of pushing, expanding and bending of pipes simultaneously, using the inner tool of mandrel. Characteristics of mandrel bending strongly depend on the integrated shape and dimensions of the mandrel.

Elbows manufactured by using hot mandrel bending have advantages of small thickness deviation and shorter bending radius than those of any other bending method type.

Extrusion Method

In cold Extrusion method, a pipe with the same diameter as a finished product is pushed through a die and formed into its desired shape. Usually applied to stainless steel small to medium sizes elbows.

Here you can see that a cut pipe piece is pushed into the cold bending die. Proper lubrication is required to avoid excessive friction and protect surface finish of the final elbow. In next stage, the elbow is sent for heat treatment and machining before its offers for visual and dimension inspection.

UO Method

UO method is used to manufacture medium size elbow, tee, and reducers. The plate is cut out into a specially designed shape, it is formed first into a U-shape using a die and then into an O-shape or into a tubular form using another die, that is why this method is known as UO method.

Once the fittings formed in tumbler shaped it is welded from inside and outside of the closing seam. A very large size elbows are made of two separate pieces of plate. But follow the same process. Here you can see the same. In next stage, the elbow is sent for heat treatment and machining before its offers for visual and dimension inspection.

掃二維碼用手機看

- Telphone- 0317-6165555 6689999

- E-mail- 798758696@qq.com

- Address- Yanshan County Industrial Park, Cangzhou City, Hebei Province

- Telphone- 0317-6165555 6689999

- E-mail- 798758696@qq.com

- Address- Yanshan County Industrial Park, Cangzhou City, Hebei Province